Products

Your Location: FuYou New Material - Products - Thermoplastic Honeycomb - Thermoplastic honeycomb Natural

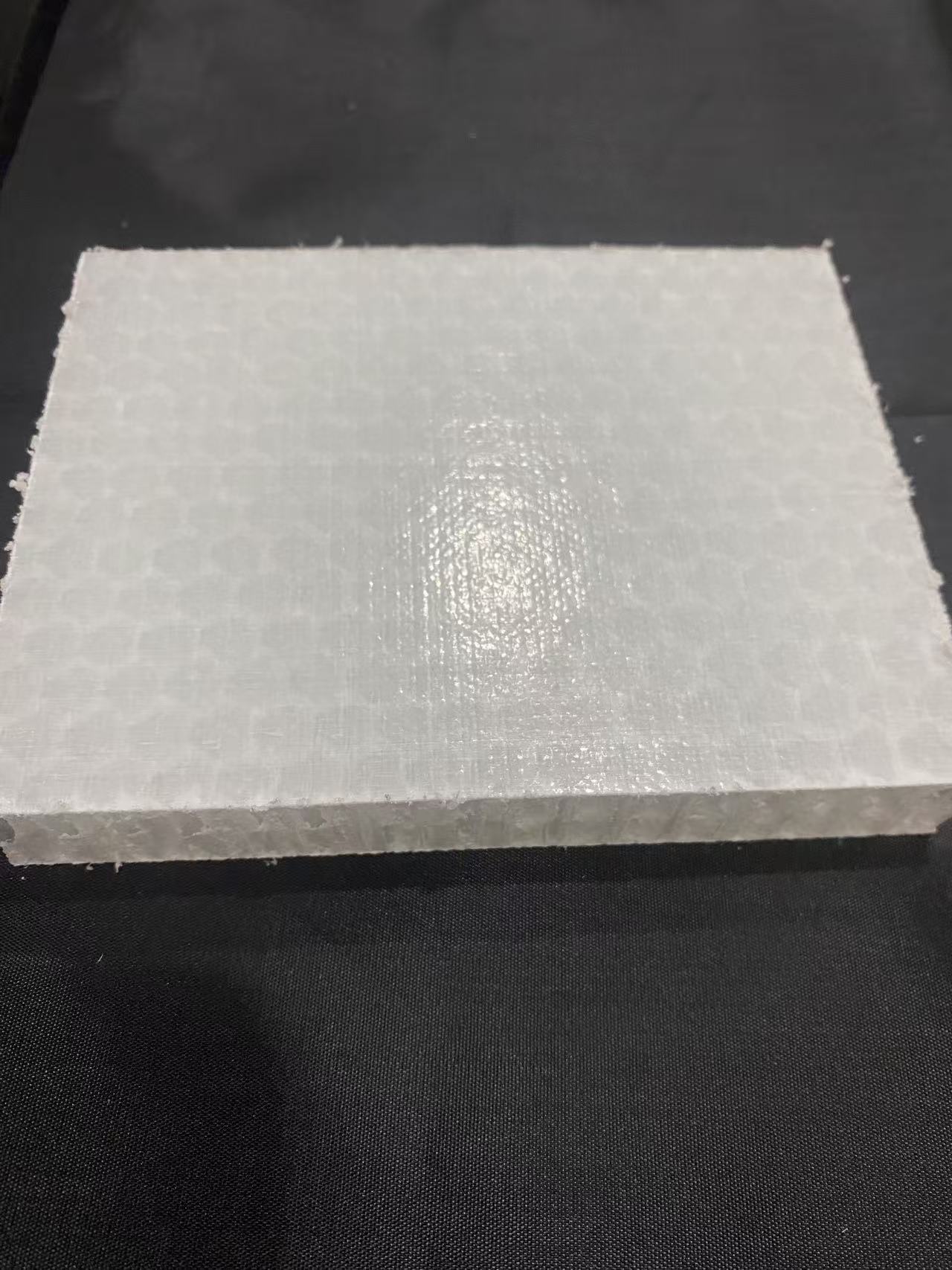

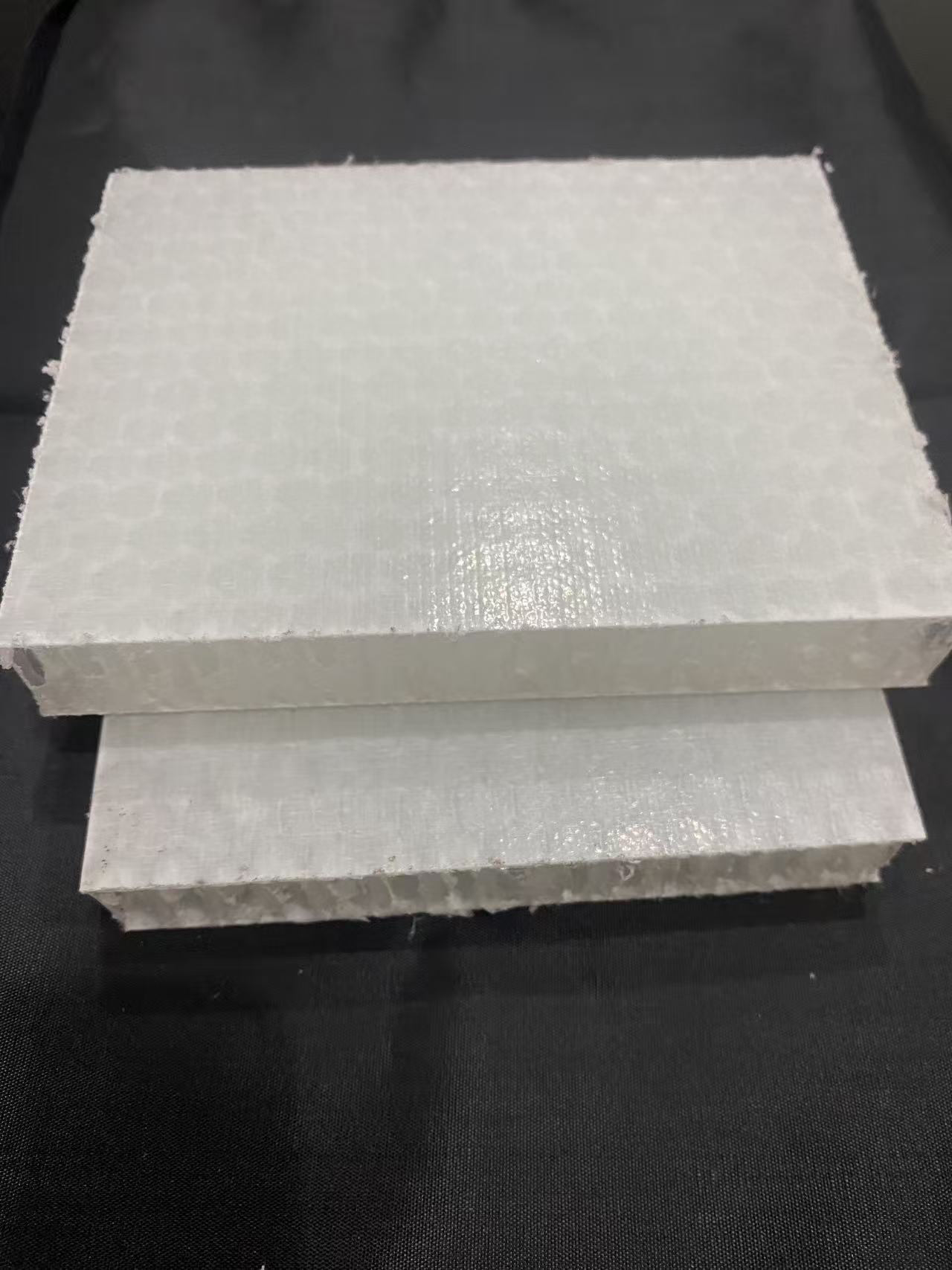

Specification

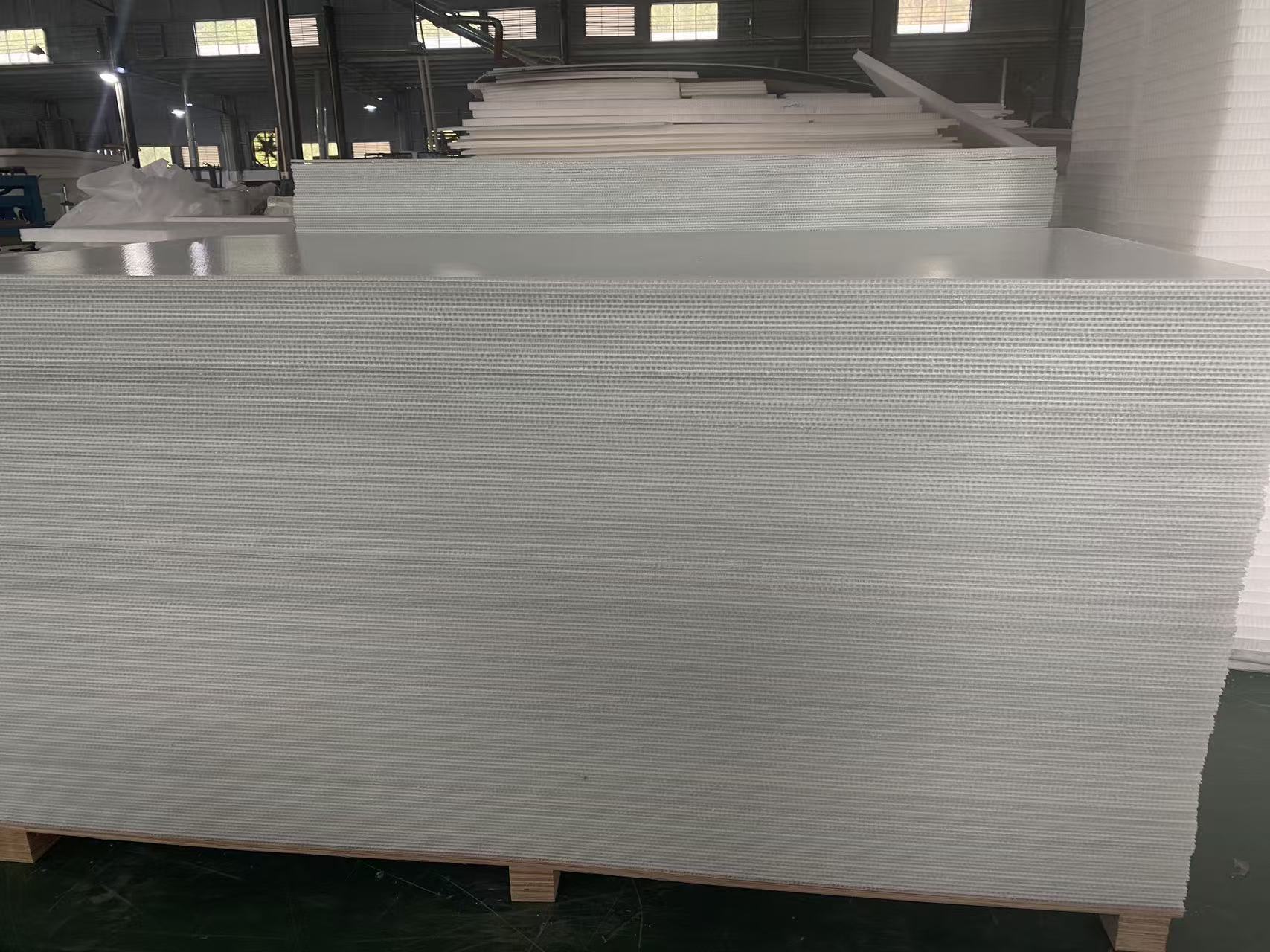

| Material | Polypropylene+fiberglass |

| Color | Natural |

| Thickness | Customized 6-50mm |

| Cell diameter | Customized 6-12mm |

| Length | 1-6m |

| Width | 0-1.6m |

| Core Density | 100kg/㎥(Customized : 70-140kg/㎥) |

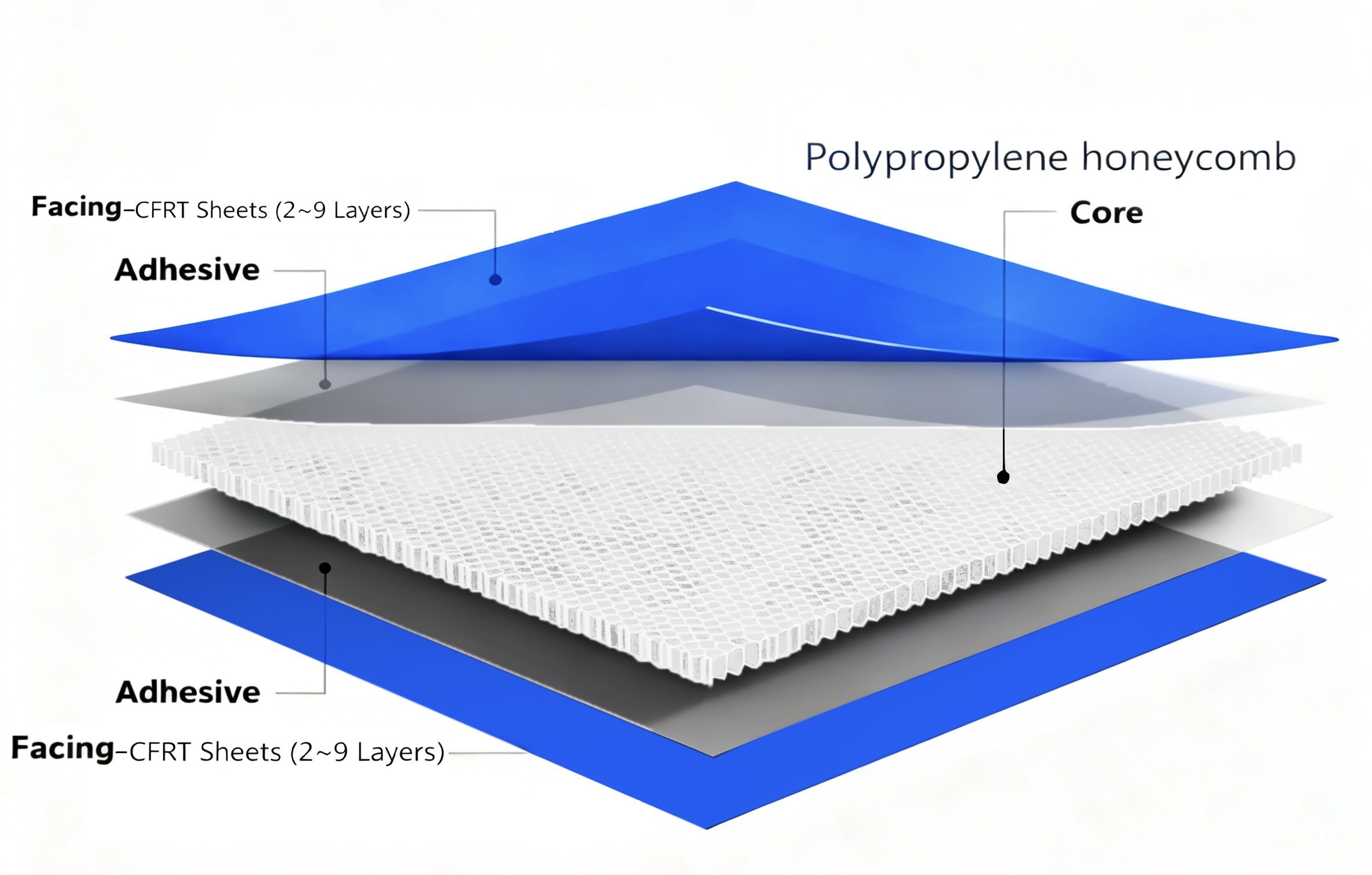

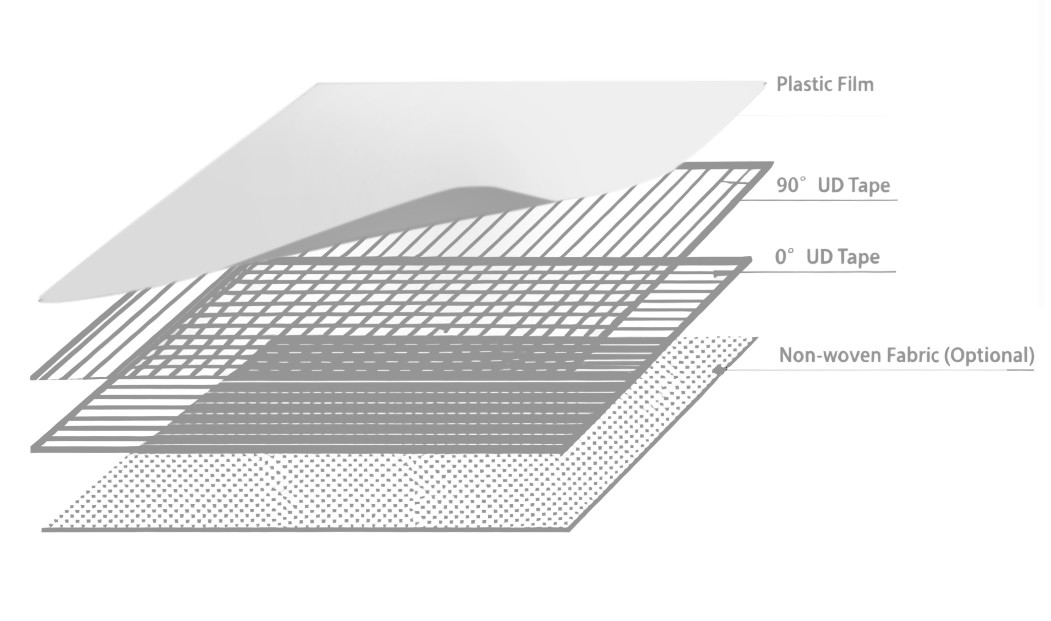

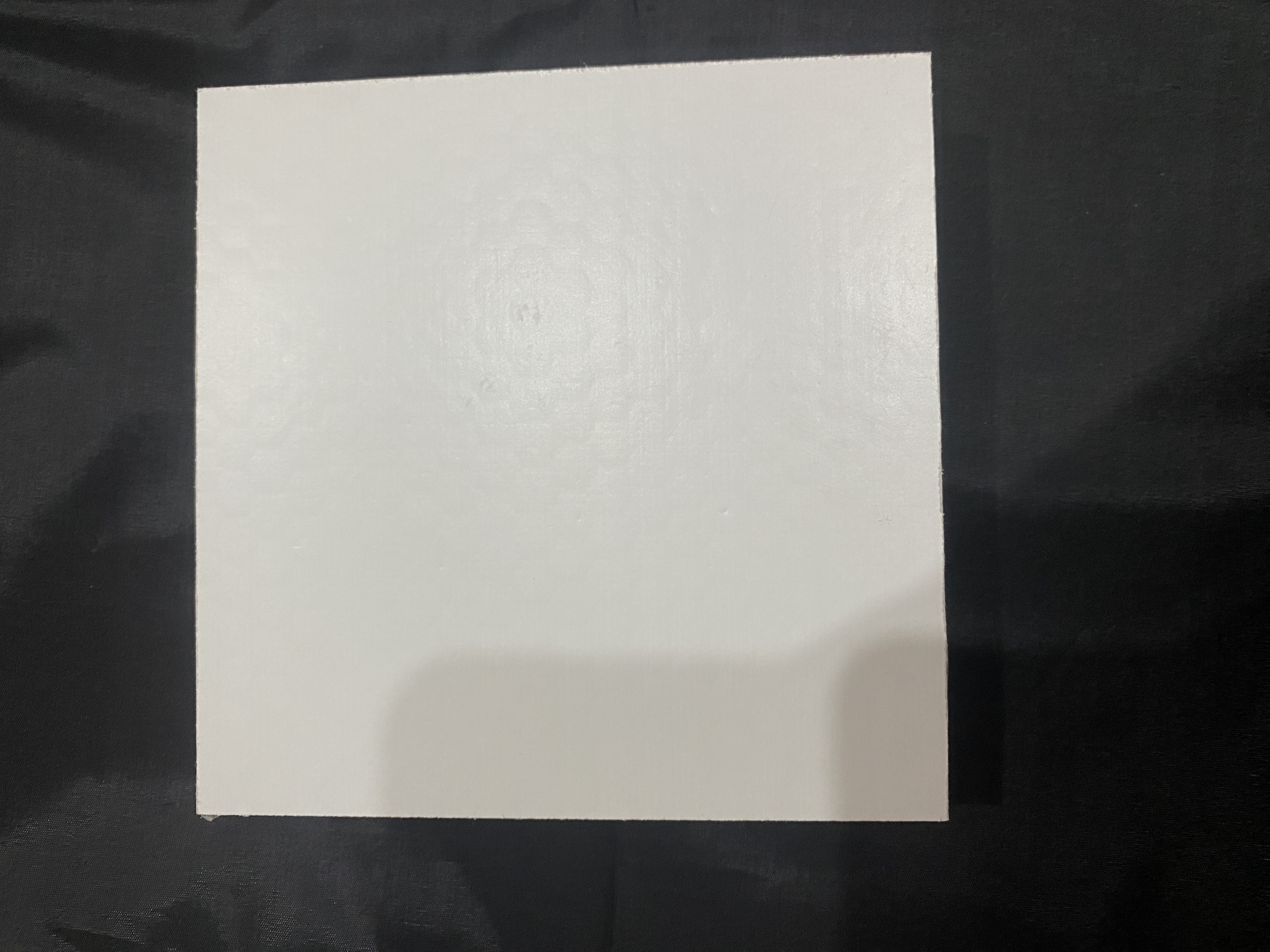

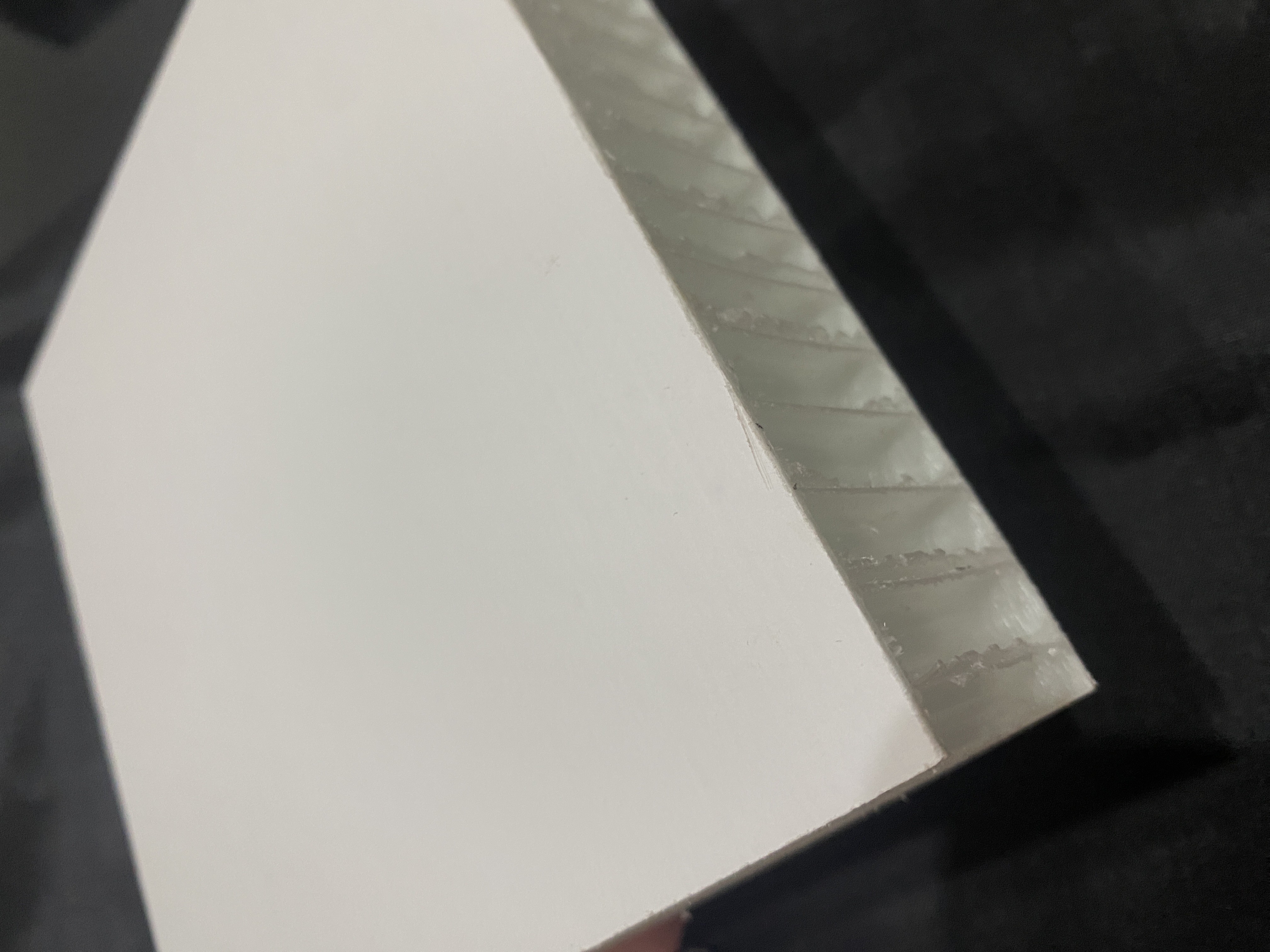

Facing-CFRT Sheets

CFRT (Continuous Fiber Reinforced Thermoplastic) is a high-performance composite material. It is composed of continuous unidirectional fibers (such as glass or carbon fiber) and a thermoplastic matrix (e.g., PP, PA, PPS) combined via a specialized impregnation process. It retains the high strength and modulus of the reinforcing fibers while incorporating the high toughness and recyclability of the thermoplastic polymer. Thanks to its continuous fiber structure and thorough resin impregnation, CFRT exhibits far superior mechanical properties to discontinuous fiber composites like GMT and LFT. It is typically supplied as a prepreg tape and can be processed using rapid hot-pressing techniques, finding broad applications in automotive, transportation, and sports equipment industries.

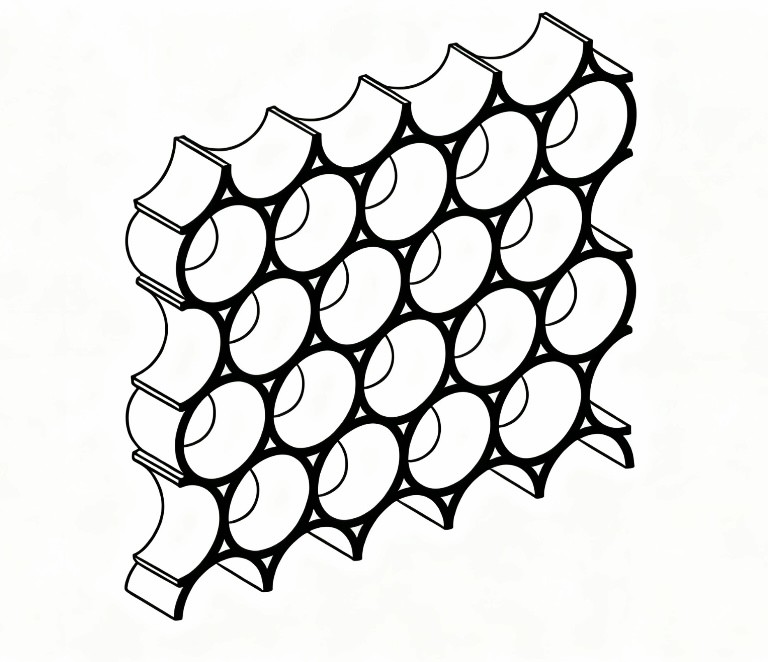

Core-Polypropylene honeycomb

The PP honeycomb core is fundamental to the sandwich structure, leveraging a combination of the polypropylene material's properties and the honeycomb geometry. This results in a lightweight, high-strength core with outstanding impact resistance, energy absorption, sound and thermal insulation, chemical resistance, moisture protection, and vibration damping capabilities.

Physical properties of thermoplastic honeycomb panels

Thickness | 10mm | 12mm | 15mm | 18mm | 20mm |

Core Density(kg/㎥) | 100 | 100 | 100 | 100 | 100 |

Surface Density (kg/m²) | 2.88 | 3.08 | 3.38 | 3.68 | 3.88 |

Flexural Strength (MPa) | 25 - 35 | 35 - 50 | 50 - 70 | 65 - 90 | 75 - 105 |

Elastic Modulus (Flexural) (MPa) | 1300 - 2200 | 1800 - 3000 | 2800 - 4500 | 3800 - 6000 | 4500 - 7000 |

Compressive Strength (Flatwise)(MPa) | 2.0 - 3.5 | 2.0 - 3.5 | 1.8 - 3.2 | 1.6 - 2.8 | 1.5 - 2.6 |

Thermal Conductivity (W/(m·K)) | 0.09 - 0.12 | 0.09 - 0.12 | 0.09 - 0.12 | 0.09 - 0.12 | 0.09 - 0.12 |

Core Advantages of PP Thermoplastic Honeycomb

Extremely low density for significant weight reduction.

Exceptional strength-to-weight and stiffness-to-weight ratios; performance rivals metal when composited.

Excellent toughness and energy absorption; deforms to absorb impact rather than fracturing.

100% thermoplastic, allowing for repeated reprocessing and full alignment with circular economy goals.

Can be thermoformed into complex shapes, and is easy to cut and join, offering high design freedom.

Resistant to chemicals and moisture, with good sound and thermal insulation properties.

Comparative advantages with different panels

Thermoplastic Honeycomb vs. Other Panels | ||

vs. Steel | vs. Plywood | vs. FRP/Foam |

Lighter | Lighter & easy to assemble | Lighter |

Easy assembly | Impact resistant | Easy assembly |

Impact resistant | Waterproof & fire retardant | Impact resistant |

Non-rusting | Durable (fiber-reinforced) | Waterproof |

Food-safe | Repairable | Delamination-proof |

Repairable | Food-safe | Recyclable |

Thermal insulation | Eco-friendly & recyclable | Repairable |

| Long life | Oil-resistant | Long life |

Long life | Long life | Prone to delamination |

Application

WhatsApp

WhatsApp