Revolutionizing the Future of Construction: GFRP Honeycomb Panels, Redefining Concrete Aesthetics and Efficiency

Time:2025-11-05

Revolutionizing the Future of Construction: GFRP Honeycomb Panels, Redefining Concrete Aesthetics and Efficiency

Subtitle: Eliminate Secondary Plastering. Achieve High-Value, High-Efficiency Green Construction.

In today's rapidly evolving construction industry, are you still grappling with the heaviness, inefficiency, and inconsistent concrete surface quality of traditional formwork? Do you seek a solution that enhances both building quality and overall cost-effectiveness? The answer is here—**GFRP (Glass Fiber Reinforced Polymer) Honeycomb Formwork Panels** are leading a revolution in the formwork sector with their game-changing performance.

What is GFRP Honeycomb Formwork?

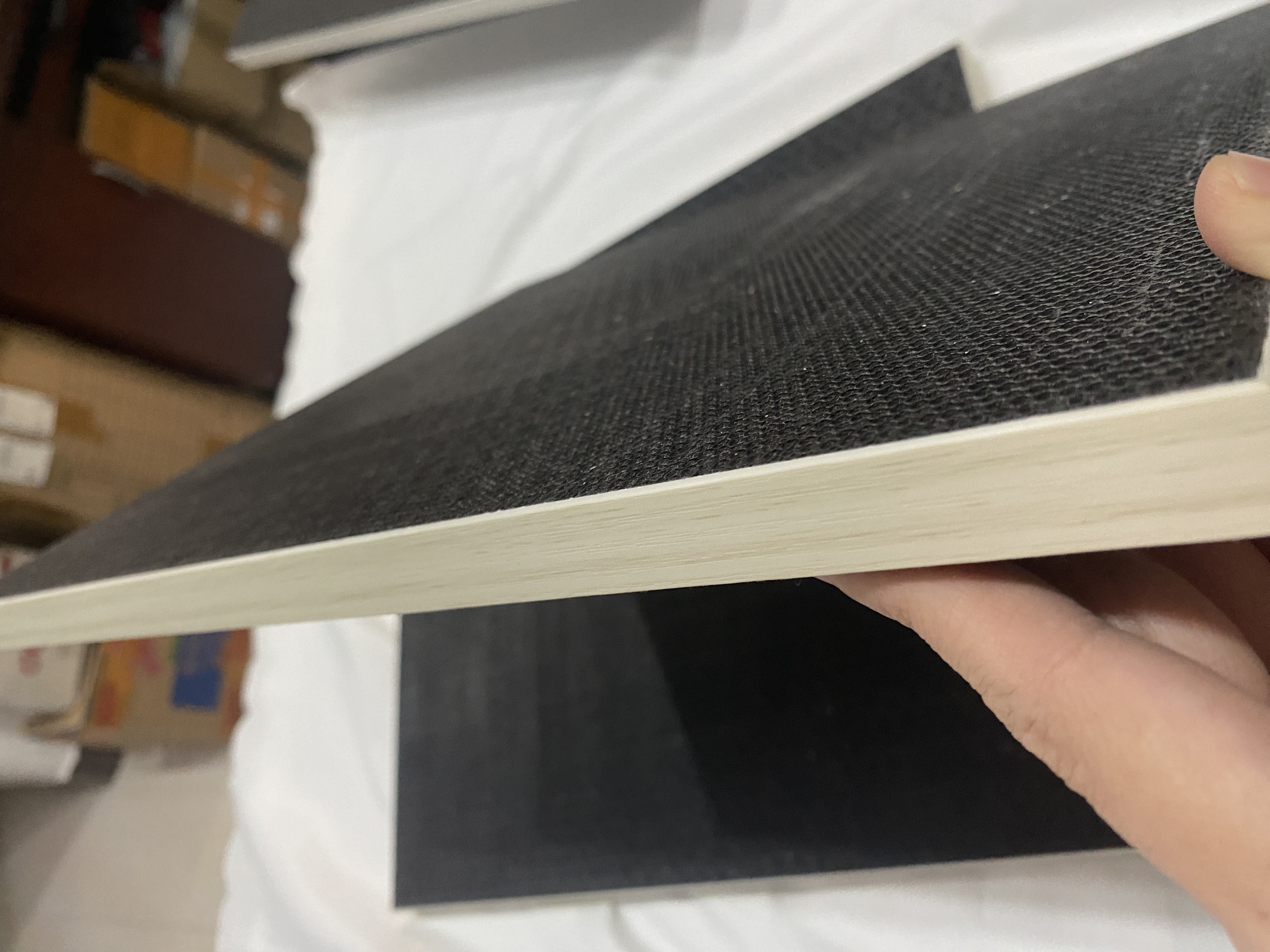

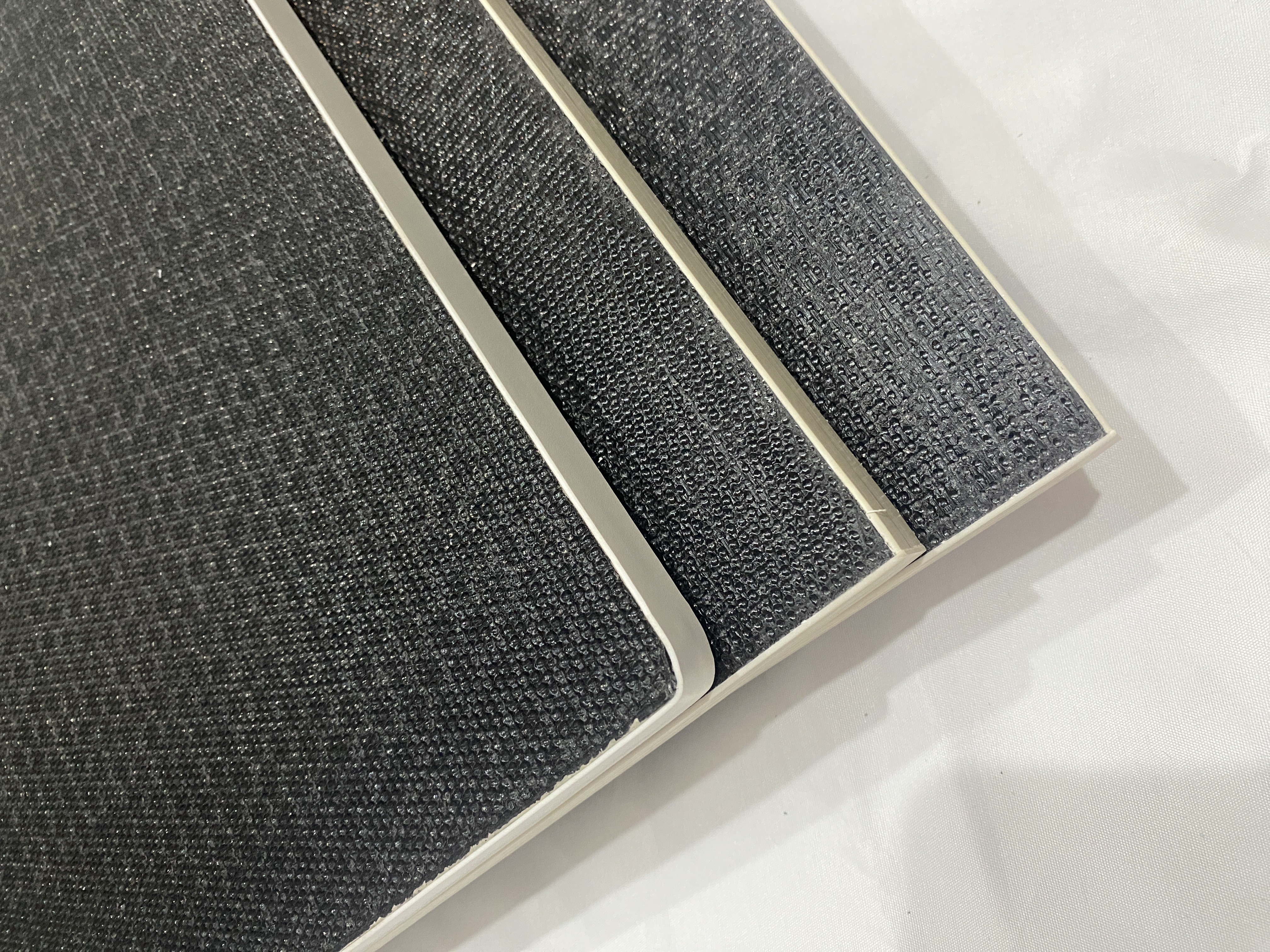

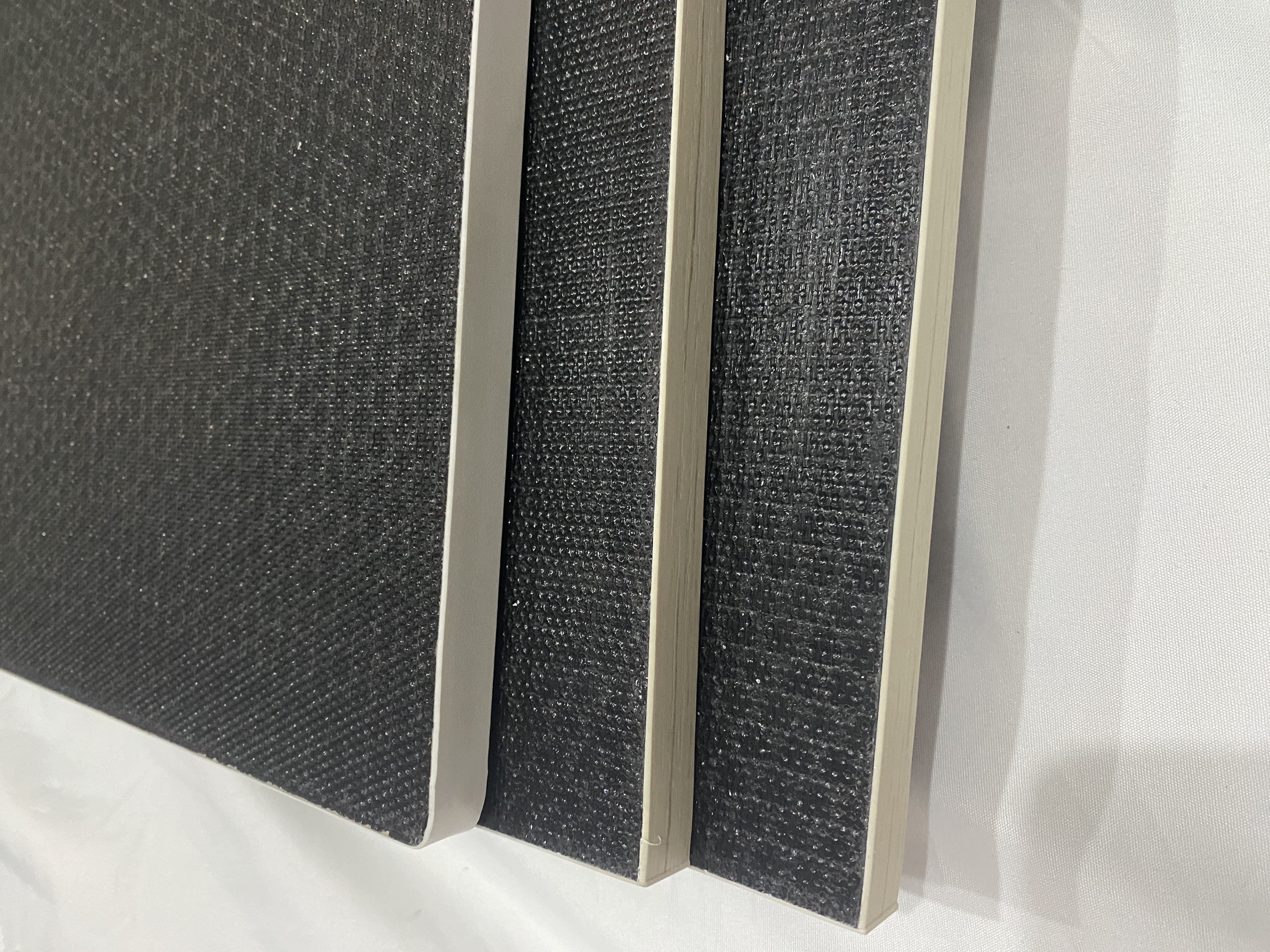

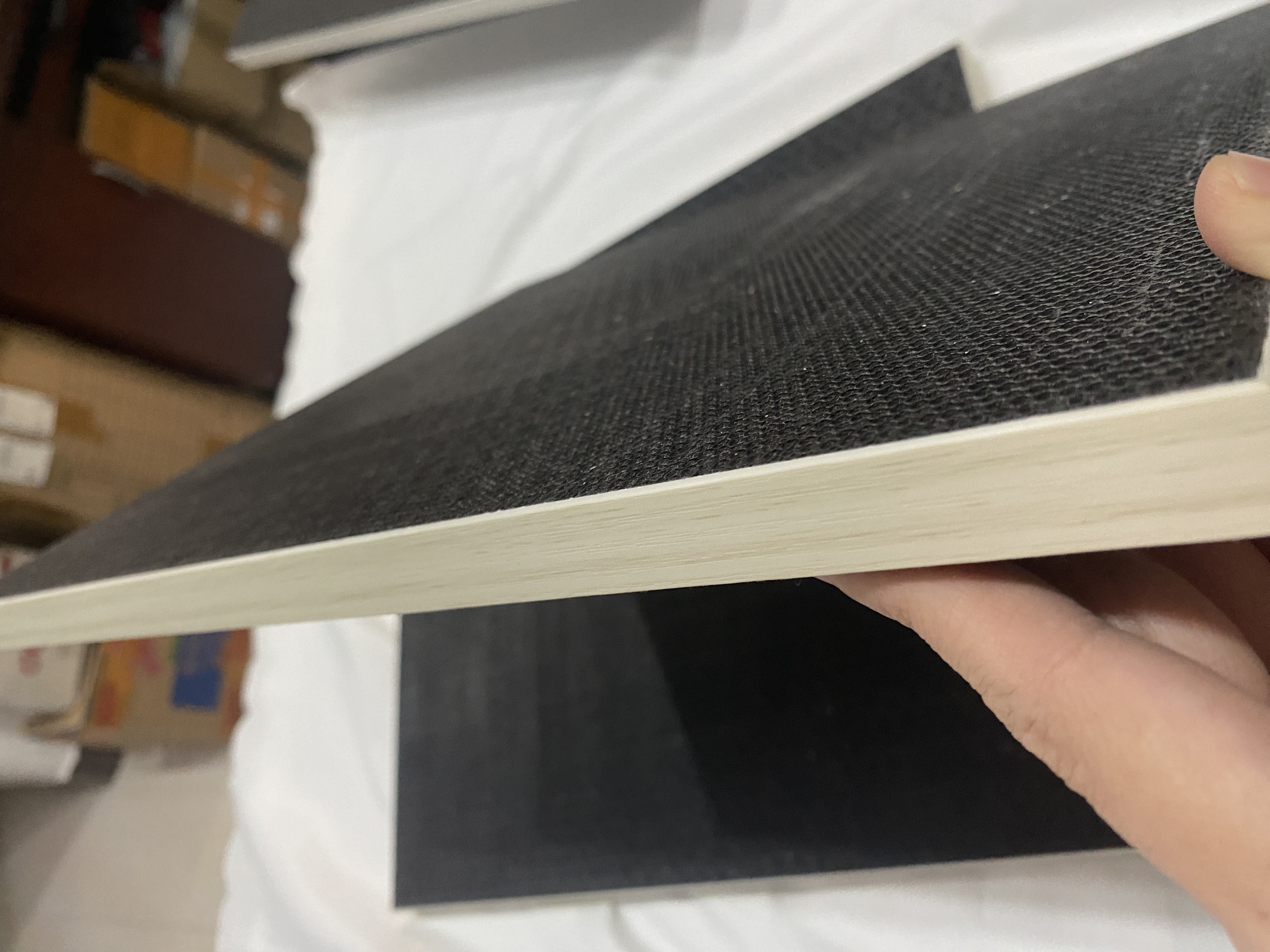

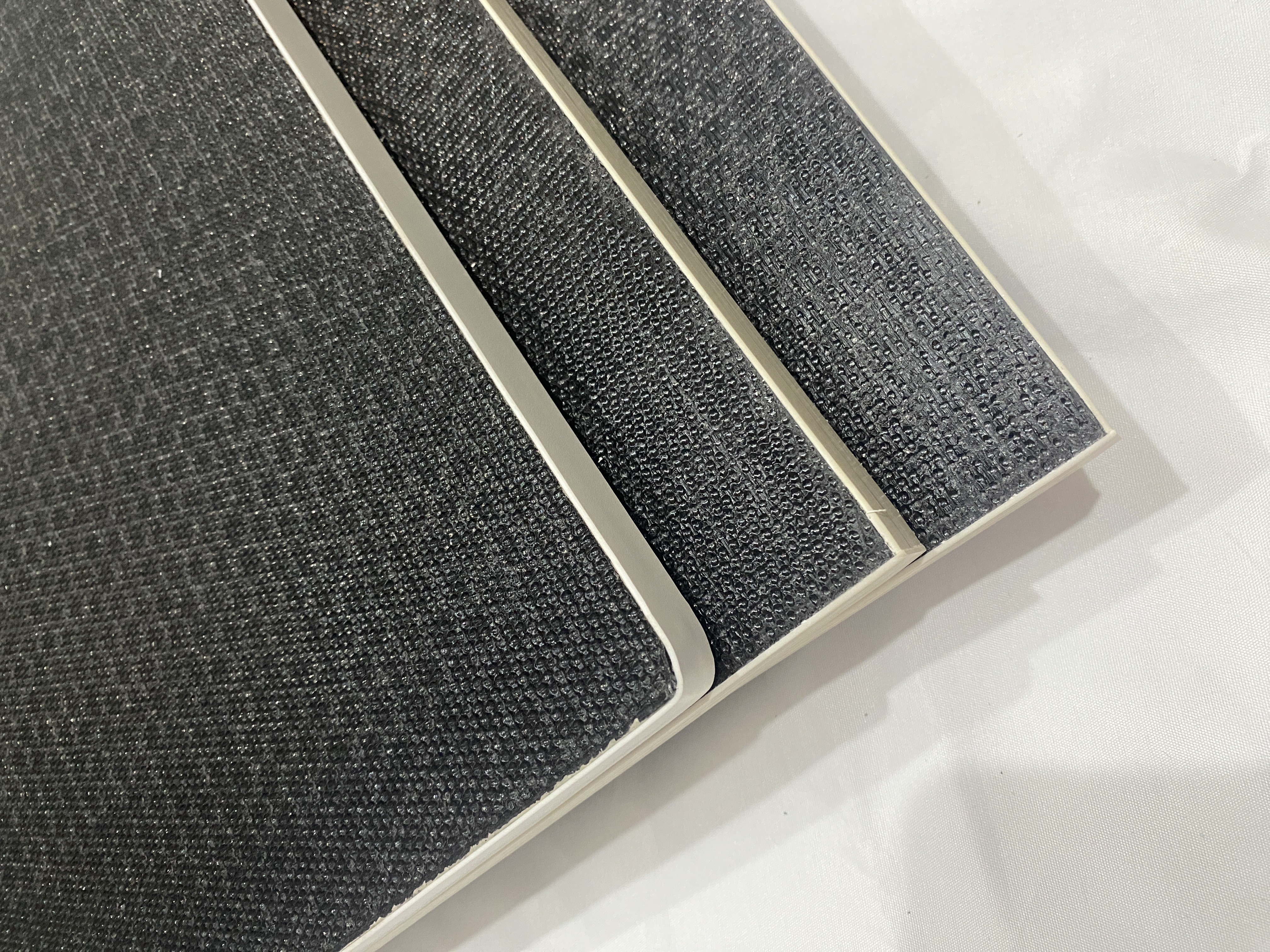

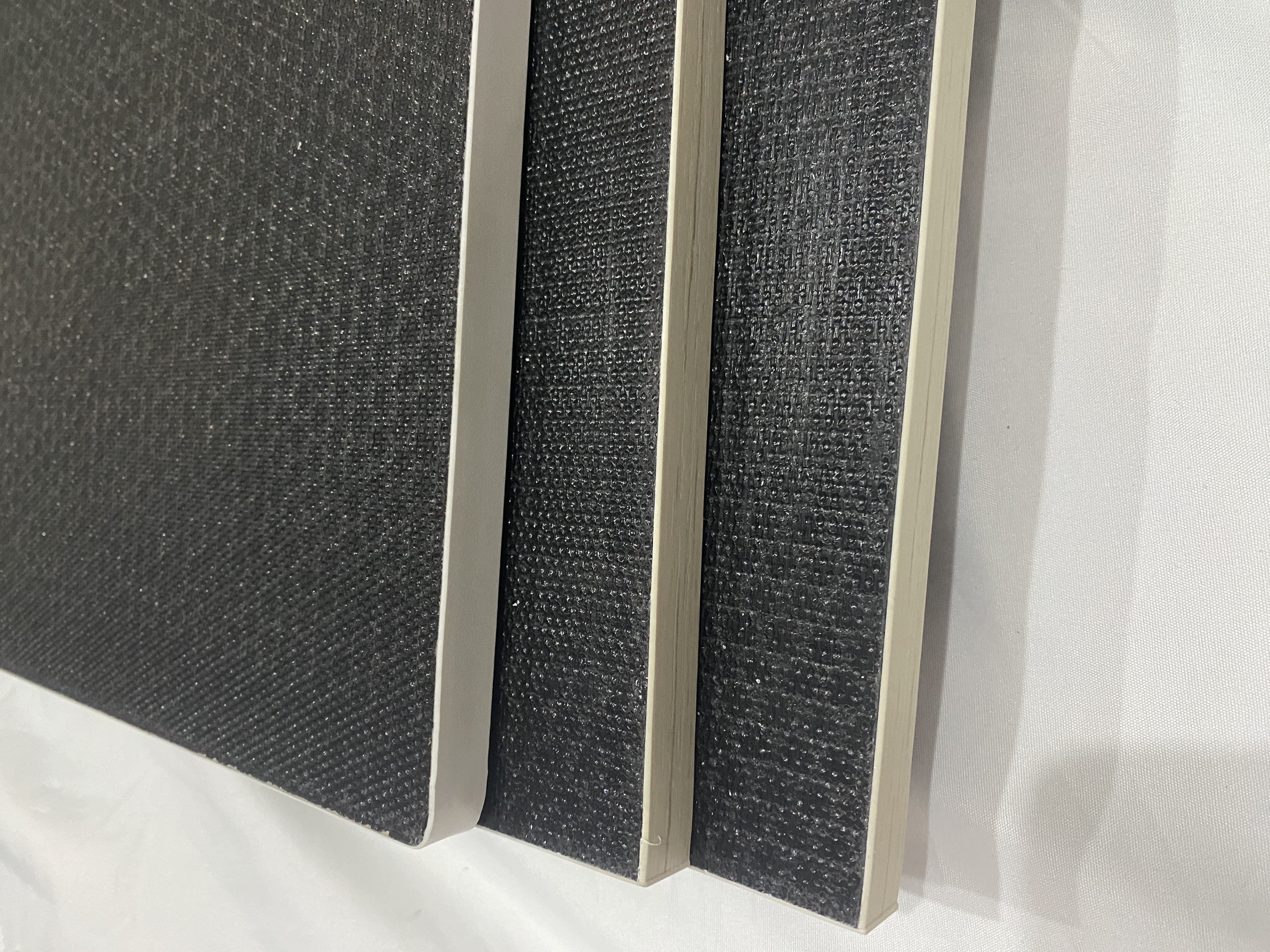

What is GFRP Honeycomb Formwork?It is a high-performance formwork system made from high-strength glass fiber skins laminated to a lightweight yet robust honeycomb core using advanced composite manufacturing techniques. This "sandwich" structure grants it superior properties that surpass wood, steel, and conventional aluminum, making it the ideal choice for high-end concrete projects.

Why Choose Our GFRP Honeycomb Formwork? Five Core Advantages Define the New Standard1. Perfect Surface, Unmatched AestheticsMirror-Finish Concrete: The panel's surface is smooth as glass, resulting in concrete that is dense, uniform in color, and achieves a **high-quality architectural fair-faced concrete** finish directly upon stripping. This eliminates the need for time-consuming and costly secondary plastering, revealing the pure structural beauty of the architecture and adding unique artistic value to your project.

2. Light as a Feather, Strong as RockUltra-Lightweight: It weighs only

one-fifth of traditional steel formwork and is even lighter than aluminum formwork. Workers can handle and install panels with ease, significantly reducing labor intensity, increasing formwork erection efficiency by **over 30%**, and minimizing reliance on heavy machinery.

Exceptional Strength: The unique honeycomb structure provides an unparalleled strength-to-weight ratio, capable of withstanding the high fluid pressure of wet concrete, ensuring construction safety and structural accuracy.

3. Long Service Life, Superior ROIOutstanding Durability: Excellent corrosion and weather resistance make it impervious to sun, rain, and exposure to chemicals, maintaining stable performance even in harsh environments like coastal or industrial sites.

Proven Economical: While the initial investment is higher, its exceptionally long service life (

200+ reuses possible) and minimal maintenance requirements result in a far lower long-term cost than wooden formwork and offer greater comprehensive value compared to aluminum systems. It is a true "invest once, profit long-term" solution.

4. Green & Sustainable Capable of being reused hundreds of times, it drastically reduces timber consumption and construction waste. Its manufacturing process is also aligned with environmental standards, helping your project easily qualify for green building certifications (e.g., LEED, BREEAM) and enhancing your corporate image.

5. Design Flexibility, Empowering Creativity

* Offers good cut-to-size capability and some bendability, allowing it to easily adapt to complex designs such as curved walls, columns, and special architectural features, seamlessly turning architects' creative visions into reality.

Application Scenarios: Where Does It Excel?

High-End Commercial & Public Buildings: Museums, art galleries, theaters, airport terminals—any landmark project demanding the highest standard of concrete finish.

High-Rise Building Cores: Its lightweight nature is critical for the efficient climbing formwork systems used in core walls.

Infrastructure Projects: Ideal for tunnel, bridge, and utility tunnel lining, producing smooth interior walls that reduce operational ventilation resistance.

Precast Concrete Plants: Serves as the perfect mold for producing high-quality precast concrete elements.

We Offer More Than Just a Product

When you choose us, you get more than top-tier formwork; you get a complete solution:

Expert Technical Consultation: Our engineering team provides end-to-end support, from formwork design and backing system configuration to on-site guidance.

Customization Services: We can custom-manufacture panels to specific sizes and curvatures based on your project drawings.

Comprehensive After-Sales & Training: We ensure your team can use our products skillfully and efficiently.

Are you looking for a partner that can simultaneously elevate construction quality, on-site efficiency, and project value?

Contact us now to request a free sample and a proprietary technical solution! Let our innovative GFRP Honeycomb Formwork lay the foundation for your next project's success.

WhatsApp

WhatsApp